Introduction: The Rise of Intelligent Robotics

In the ever-evolving world of logistics, robotics has moved from experimental prototypes to indispensable tools in modern warehousing. Amazon, a global leader in e-commerce and technological innovation, continues to push the boundaries with Vulcan—a warehouse robot that doesn’t just move items but feels them.

This leap in tactile feedback marks a pivotal shift in how robots interact with physical objects, blurring the lines between human dexterity and machine precision. But what makes Vulcan different, and why should business leaders, marketers, and tech enthusiasts take note?

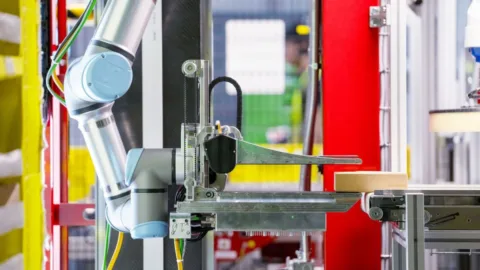

Image Credits: Amazon

Meet Vulcan: Amazon’s Touch-Sensitive Robot

Amazon recently introduced Vulcan, a dual-armed robot designed to enhance efficiency in warehouse operations. Unlike its predecessors, Vulcan isn’t just about brute force or speed—it’s about precision through touch.

With one arm dedicated to repositioning items and the other equipped with a suction cup and camera, Vulcan can identify, grasp, and rearrange inventory inside storage compartments. This capability stems from its integration of force sensors that simulate a sense of touch—an extraordinary development in the robotics space.

How Vulcan Works: A Technological Breakdown

The magic behind Vulcan lies in its smart use of hardware and data. Here’s how:

Dual Arm Functionality: One arm manipulates items to clear the way, while the other picks and places products.

Vision & Tactile Combo: The picking arm uses a camera to identify items and a suction mechanism to lift them.

Touch Feedback: Force sensors allow the robot to detect resistance, ensuring gentle handling of fragile goods and avoiding damage.

Self-Improving Algorithms: Vulcan’s learning system adapts with each interaction, gradually improving its ability to manage Amazon’s diverse product inventory.

These enhancements contribute significantly to reducing error rates, optimizing packing time, and ensuring item safety during transit.

Training the Machine: Data-Driven Precision

To build Vulcan’s capabilities, Amazon trained the robot on a massive dataset that included physical, force, and touch feedback. This real-world data enabled the robot to understand not just where to pick an item from—but how to pick it, depending on shape, size, and material.

As a result, Vulcan can now successfully pick and process around 75% of the products in Amazon’s inventory, making it one of the most versatile robots in their lineup.

Deployment and Real-World Impact

Vulcan has already been deployed at Amazon fulfillment centers in Spokane, Washington, and Hamburg, Germany. So far, it has processed over 500,000 customer orders, streamlining operations and showcasing the tangible benefits of robotics integration.

The real-world deployment confirms Vulcan’s potential to scale, and with time, we may see similar smart robotics systems used across various sectors—from healthcare logistics to urban last-mile delivery.

The Bigger Picture: Robotics in Amazon Warehouses

Vulcan is the latest in Amazon’s extensive robotics ecosystem, which includes hundreds of thousands of robotic units working in tandem with human employees. These machines carry out tasks ranging from scanning and sorting to picking and transportation.

Amazon positions its robotics as augmentation tools rather than human replacements, emphasizing that their purpose is to improve safety, reduce strain, and increase overall throughput in warehouses.

According to Amazon Robotics, their goal is to “create a collaborative environment where robots do the heavy lifting so humans can focus on higher-level problem-solving.”

Human vs. Machine: Addressing Workforce Concerns

Despite Amazon’s positive stance, concerns persist about job displacement due to automation. Critics argue that smart robots like Vulcan could lead to reduced demand for manual labor. However, Amazon maintains that these innovations create new types of jobs, including roles in robot maintenance, AI monitoring, and warehouse analytics.

As the conversation around robotics and employment evolves, businesses must prepare for a hybrid workforce model, where collaboration between human skills and robotic efficiency becomes the norm.

Conclusion: What Vulcan Means for the Future

Amazon’s Vulcan represents more than a robotic advancement—it signifies a shift toward empathetic automation where machines understand and react to the physical world. With the ability to feel, learn, and adapt, Vulcan sets a new benchmark for what’s possible in warehouse robotics.

For tech enthusiasts, Vulcan showcases the rapid progress of AI and machine learning in physical environments. For entrepreneurs, it underscores the importance of adopting emerging tech early to stay competitive.

Stay updated with the latest in automation, robotics, and AI by subscribing to Trenzest’s newsletter—where innovation meets execution.