For decades, the dream of a true “robot butler” has been stalled by a single, stubborn engineering hurdle: human dexterity. While robots can build cars and perform backflips, simple tasks like clearing a dinner table or loading a dishwasher remain frustratingly complex. The human hand, with its thousands of touch receptors and delicate pressure sensitivity, is a masterpiece of biology that has proven nearly impossible to replicate without spending millions.

Until now.

On Thursday, a new startup called Sunday Robotics (or simply “Sunday”) emerged from stealth mode to challenge the status quo. Founded in April 2024 by robotics experts Tony Zhao and Cheng Chi, the company claims to have cracked the code on household autonomy—not with expensive hardware, but with a radical new approach to training data.

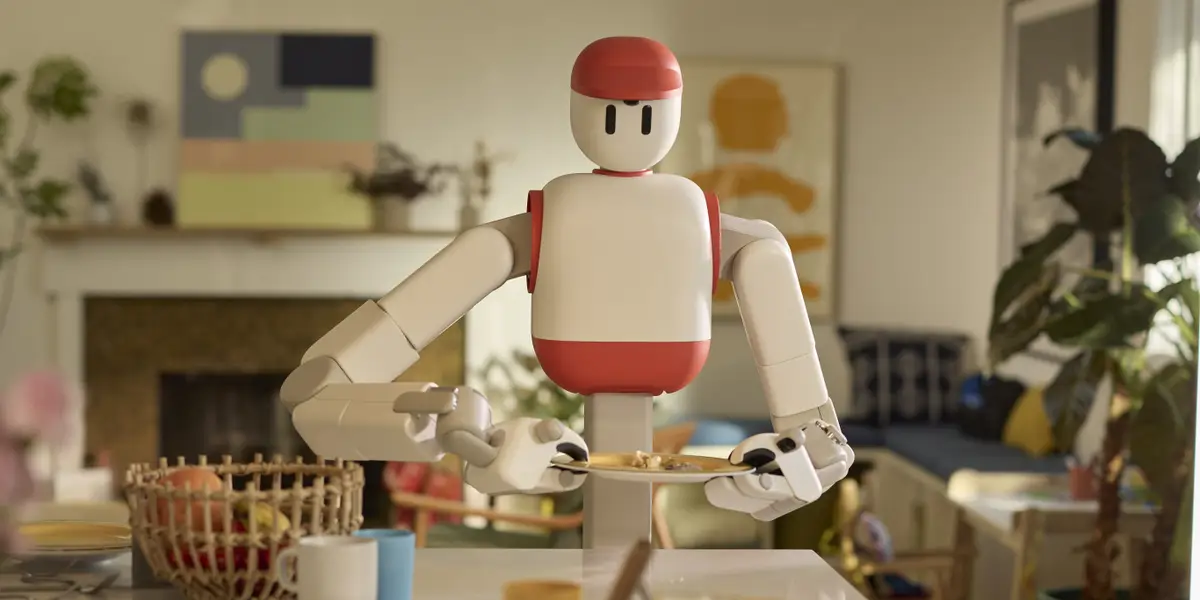

Meet Memo: The Robot That Handles Fine China

Sunday’s debut product is Memo, a fully autonomous home robot mounted on wheels designed to navigate the tight corners of a modern home. In a video released on X (formerly Twitter) by co-founder Tony Zhao, Memo was shown seamlessly moving from a dining room to a kitchen, clearing dishes, and loading them into a dishwasher without human intervention.

The demonstration highlighted capabilities that have long eluded consumer robots:

Fragile Object Manipulation: Memo was filmed picking up two wine glasses—objects notorious for shattering under robotic grip—with a single hand.

Complex Chores: Beyond dishes, the robot demonstrated the ability to fold socks and operate an espresso machine.

Consistency: According to Zhao, Memo broke zero wine glasses across more than 20 live demonstration sessions, a statistic that signals a major leap in reliability.

“Today, we present a step-change in robotic AI,” Zhao announced, marking Sunday’s official entry into the competitive robotics market.

The Dexterity Bottleneck

To understand why Memo is significant, one must understand the problem it solves. Replicating the dexterity of a human hand is one of the most capital-intensive challenges in engineering. As Tesla CEO Elon Musk noted during an earnings call in October, the sheer density of touch receptors in a human hand makes it incredibly difficult to model artificially.

Historically, companies have tried to solve this by “teaching” robots through teleoperation. In this method, a human controls the robot remotely using joysticks or VR rigs to perform tasks, which the robot records and learns from. However, these teleoperation rigs are bulky, complex, and prohibitively expensive, costing upwards of $20,000 per unit. This high barrier to entry has created a massive data bottleneck; there simply aren’t enough affordable rigs to gather the millions of hours of training data needed to make robots smart.

The Secret Sauce: A $200 Data Glove

Sunday Robotics has bypassed the industry standard entirely. Instead of relying on expensive teleoperation rigs or purely synthetic simulations, Zhao and Chi developed a proprietary data collection glove.

This device is designed to mimic the geometry of Memo’s “Lego-like” hands. The brilliance of this approach lies in its simplicity and cost-efficiency:

Cost: The glove costs approximately $200 to produce, which Zhao notes is “two orders of magnitude higher capital efficiency” compared to a $20,000 teleoperation setup.

Scalability: Because the gloves are portable and affordable, data collection isn’t confined to a lab. Sunday has already deployed these gloves to over 500 data collectors across the United States.

“In robotics, if the only thing we can rely on is teleoperation, to gather the amount of training data it would take like decades for sure,” Zhao explained in an interview.

Distributed Learning: Training in the Real World

By distributing these gloves to hundreds of paid collectors, Sunday is gathering training data from real-world environments—messy kitchens, cramped laundry rooms, and cluttered living spaces—rather than sterile laboratories.

When a human wears the glove to perform a specific task, such as picking up a fragile glass, the sensors record critical nuances like the angle of approach and the exact amount of force applied. This data is then fed back to Memo, allowing the robot to “feel” and understand the physics of household objects before it ever touches them.

The Future of Home Automation

With 500+ trainers currently feeding data into the system, Sunday Robotics is accelerating the learning curve for autonomous agents at a pace previously thought impossible. By lowering the cost of data acquisition, Sunday isn’t just building a robot; they are building a scalable framework for robotic intelligence.

As Memo prepares to roll into more homes, the promise of a robot that can finally do the dishes without breaking them is closer than ever. For the robotics industry, Sunday’s $200 glove might just be the helping hand it has been waiting for.

For more articles like this visit Trenzest.